Siemens S5 PLC’s are the workhorses of industry which is why Optima still come across them on a weekly basis. Fortunately, our talented team of engineers can apply their engineering skills to a wide variety of machines. This provides a valued upgrade service for our clients.

S5 has been so reliable that we are now upgrading from Step 5 to Tia Portal and missing out Step 7 Classic altogether.

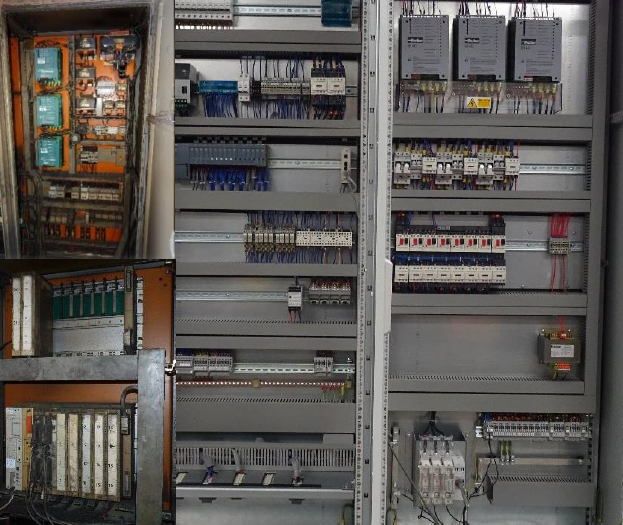

Optima were called to a customer who had a Bespoke welding machine controlled from an S5 PLC that was over 30 years old. The problems they had were the PLC regularly losing its program and an operator interface that wasn’t very user friendly. The lack of a recipe system for the different products meant product change-over times were too long.

Optima provided a custom upgrade solution that improved the machine operation as well as the reliability. A PUWER report was also carried out and the entire machine safety system – including the hydraulic control – was upgraded to meet current standards.

It’s important to consider how operators use the equipment, which is why we always write a full system specification. This allows both maintenance personnel and operators to have full input into the upgrade process. When the system is delivered, the operators are familiar and comfortable with the operation straight away. This method also allows us to improve the machine process and operation so that the user interface with the machine is more user-friendly.

Optima suggested improvements such as a full product recipe package that allows fast changeover between products. A new safety system was designed to the required performance level according to EN-ISO13849.

The customer now has a machine that works on-time, every time whilst also being straightforward and intuitive for operators to use.

Our philosophy is “don’t just upgrade when you can upgrade and improve”. Optima can help you achieve improved machine performance and reliability in your processes. On request, Optima can provide you with personal support for very specific requirements. From consultation and implementation to final project completion, Optima offers a comprehensive modernisation service package.

Optima are one of only 7 authorised Drives and Motion Partners in the UK. Our certification as a Siemens Solution Partner Automation is a guarantee of high quality when it comes to tailor-made solutions that can meet the needs of the future in the areas of automation and drives. You profit from the innovative products and systems of Siemens and from our excellent know-how of solutions and industry.

Totally Integrated Automation Portal (TIA Portal) enables complete access to the entire digitalised automation, from digital planning and integrated engineering to transparent operation. This makes visibility of the factory manufacturing process much easier.