Tag Archives: Drives

Digital cloud-based asset monitoring is offered worldwide

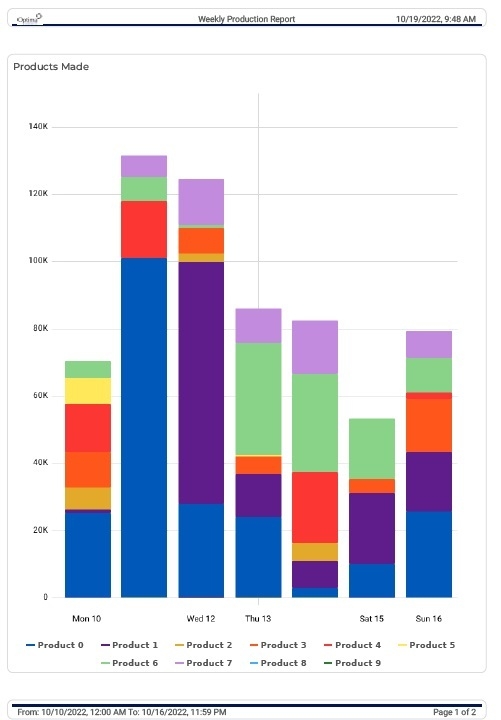

Our new digital cloud-based services platform can be used worldwide. The software means Optima can monitor and track your assets in real time. You can view device history, schedule tasks and monitor the machine via the cloud. This keeps you informed of any issues as and when they occur. Escalation thresholds can be configured, so depending on the nature of the fault, the relevant people are emailed. The monitoring system can also give daily reports via email notifications with programmable triggers.

If the machine starts operting in an unexpected way, an email is tiggered, sending messages to your maintenance and response teams We can use the system

to diagnose the issues with your hardware and ship equipment to site to rectify the problem.

These online diagnostics can be viewed 24/7 and the software can bring to your attention any faulty systems, sometime even before a breakdown happens.

Please contact us for a no-obligation dashboard trial.

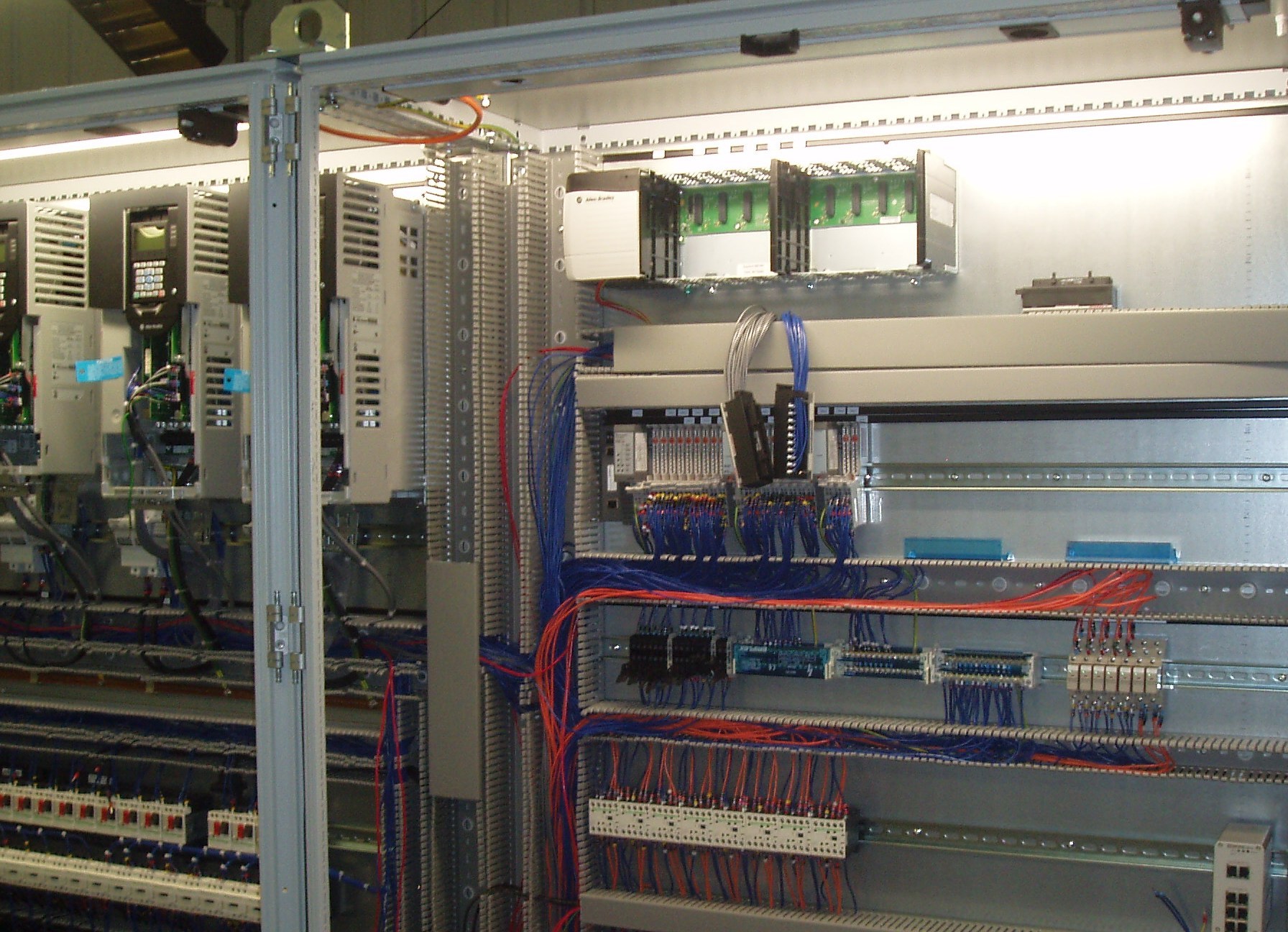

Automax and PLC5 to PowerFlex Drives and Control Logix Upgrade

Optima recently carried out an upgrade on a complex Automax-based drive system running on an obsolete PLC5 controller. The customer requirement was that the old Automax controller rack, PLC5 and obsolete DC drives were removed in one complete shutdown and replaced with the latest state-of-the-art technology.

Optima achieved this by replacing the DC drives and motors were by new AC Powerflex 753 drives and AC vector motors. Additionally, the PLC rack was replaced by a new Control Logix rack and remote IO on Ethernet. The now redundant PanelMax HMI was replaced by a new InTouch system from Wonderware.

The full scope of work included:

- Hardware calculations/rating for drives

- Customer project specifications

- Project design specification

- Circuit diagrams

- Special test documents

- Software specifications and sequence diagrams

- Installation of new panels and motors on-site

New Control Logix PLC and PowerFlex Drives Panel

Optima will be pleased to provide a no-obligation site visit to discuss how we implemented this upgrade and how we can help upgrade your machine to new supportable equipment.

Please telephone: 01254 272829 to discuss your requirements in more detail.

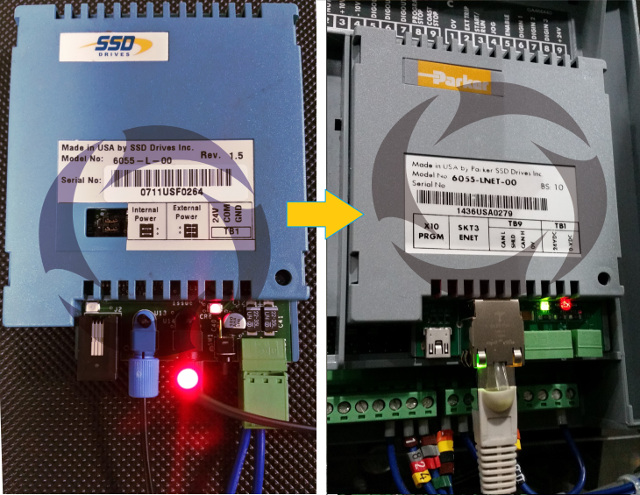

New Ethernet-based Parker Link system supercedes SSD fibre optic

Link 2 fibre optic systems are recognised for their reliability, high performance and noise-free transfer of data for web transport systems. Originally developed by SSD Drives in the 1980’s the Link technology is still widely in use today. However, now that Link 2 has officially been declared obsolete, what are the replacement options available?

In 2015, Parker officially launched the new Ethernet-based Link replacement system to selected integrators for proving. Optima were one of the first companies to successfully bring this technology to the field.

The drives upgrade was undertaken on a high-performance paper winding machine. This drive system comprises a main Siemens PLC and HMI communicating with the Parker drive system over Profibus.

Having successfully integrated over 30 Link systems since forming the company – including a 110-drive system for a coating line at a leading papermaker – you can be sure that Optima have the know-how to implement any system effectively.

Optima will be pleased to provide a no-obligation site visit to discuss how the Ethernet Link technology can replace your existing fibre-optic system or for a completely new upgrade.

Please Contact Us to discuss your requirements in more detail.

Imperial Tobacco’s Re-Branded Packaging Judged a Winner

When Imperial Tobacco decided their Lambert and Butler product was to be rebranded, Alcan Packaging and API Foils had a two-part challenge.

When Imperial Tobacco decided their Lambert and Butler product was to be rebranded, Alcan Packaging and API Foils had a two-part challenge.

The first part being the product’s design and security demands. These meant that highly accurate register control was essential because tolerances of +/-0.15mm in 70mm were required in the final product. The second part of the challenge was that three discrete production processes were needed to manufacture the product on three different sites by two different companies and with each process the material structure altered.

API Foils at Poynton had previously worked closely with Optima on a number of projects and, being aware of our experience and expertise, API contacted Optima to explore possible solutions. Continue reading

Control System Expertise and Sound Project Management

Process Line Ltd. are an engineering design company that provide lithographic plate manufacturers and the wider metal finishing industry with specialist services including the bespoke design, project management and construction of litho plate production lines, metal web finishing lines and specialist consultancy services in these fields.

Process Line Ltd. are an engineering design company that provide lithographic plate manufacturers and the wider metal finishing industry with specialist services including the bespoke design, project management and construction of litho plate production lines, metal web finishing lines and specialist consultancy services in these fields.

From its UK head office, at Yeadon nr. Leeds, the Process Line team engineer projects ranging from upgrades of individual line sections through to the construction of complete plate production lines, Process Line provides these services to clients around the globe. Continue reading

Optima Control Solutions Helping Make Britton Great

A leading film and packaging supplier has made energy savings and been given a new lease to plant equipment following a drive and controls upgrade by Optima Control Solutions Ltd (OCS). Continue reading

Food Manufacturers Opting For Optima Performance

Drives and controls are fundamental to keeping the wheels of the food industry turning. Obsolete systems can have a negative impact on productivity levels and processing operations even at the most profitable of companies. Continue reading

Optima Apply Siemens Technology in Photographic Finish

Optima Control Solutions Ltd. applied Siemens Automation and Drives equipment for the complete upgrading of a high speed lithoplate cut-to-length facility. The operators of such plants face a bewildering choice of options that can involve large variations in cost and reliability. The huge capacity of a single line means that a solution needs to be successful as any shortcomings have a high impact on output. Despite the short access times available, industrial controls and systems specialist Optima, completed a high quality Jagenberg Sheeter refurbishment for Kodak (Formerly Kodak Polychrome Graphics). Continue reading

Optima is Converting Performance into Profits

Drives, PLCs and SCADA and controls are fundamental to the converting industry, companies naturally rely on their machine control systems for production. More recently however, enterprising companies have developed their control systems to commercial advantage. Continue reading