Applying control technology to automated machinery needs a range of technical skills. Good electrical engineering ensures it’s safety, reliability and longevity.

Applying control technology to automated machinery needs a range of technical skills. Good electrical engineering ensures it’s safety, reliability and longevity.

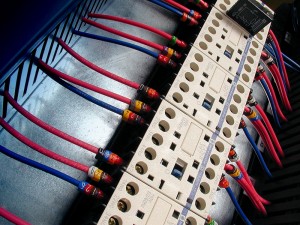

Our engineers design control systems with electrical and electronic equipment switching and controlling powers rated from milli-watts to megawatts. In the work we undertake the consequences of poor electrical engineering can be catastrophic. To ensure the high quality of engineering that is necessary we operate a design procedure regime that ensures good engineering practise on every project and encourages our engineers to be disciplined both technically and procedurally. With competent peer checking mechanisms and pre-approved component sizing techniques we guarantee our designs are good.

Using EN60204-1 design standards means that clients get consistency in there interfaces and documentation. If however our clients have their own site or corporate engineering standards we readily accommodate them.

Need more information? Browse various projects here. Our industry-specific pages also provide details about the control system projects we have completed over the years.