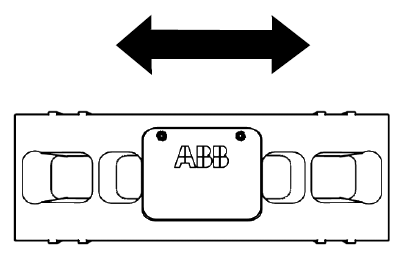

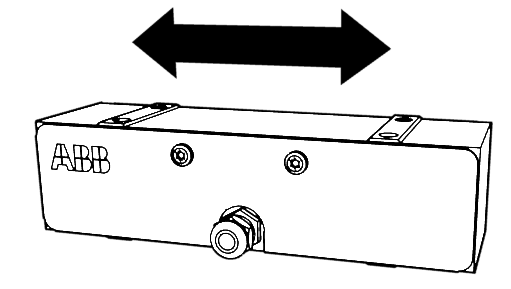

The Pressductor Radial Load Cells are ideal for applications on a wide range of web processing machinery in the converting, plastic film, printing, textiles, and other industries. The radial load cells mount directly on the roll shaft.

| SKU: | PFRL 101B-1.0 |

| MPN: | 3BSE002958R1, 4, 5, 1002 |

Description

Please contact us to discuss your exact requirements. There are a variety of loadcell sizes and mounting options available. Optima aren’t just a supplier of loadcells, we are an expert tension integrator.

For live (rotating) shaft applications, PRT load cells are available to fit a wide range of bearing and shaft sizes. A simple, pre-assembled adapter equips the load cells for use with dead (nonrotating) shafts. The load cells are easily mounted on either the inside

or outside of machine walls. By using an adapter bracket, they can also be mounted on pedestals.

Features

| Tension Max kN | 0.5 kN |

| Tension Max N | 500 N |

| Tension Max lbs. | 112 lbs |