Optima are proud to install the full range of ABB Pressductor® Loadcells on all our web processing machine upgrades and to replace old loadcells. The Pressductor® operating principle is a patented mechanical design strategy intended to further enhance measurement quality. This technology offers a significant advantage over standard strain gauge loadcells. Strain gauge load cells are often vulnerable to aspects of the machine operating environment and other factors including:

- Limited overload tolerance. The movement-based transducer operates close to the plastic deformation point of the metal in the foil grid. The overload tolerance is limited to approximately 150 to 200% of the cell capacity.

- A comparatively weak signal when compared to the Pressductor® Loadcells

- Sensitivity to environmental contaminants

Advantages of the Pressductor® Loadcells are:

- The smaller Pressductor® load cells are machined from solid blocks of corrosion-free stainless steel, giving strength and rigidity, and they do not need seals.

- Their permissible application range is extensive – approximately 30:1 overload capability with no performance deterioration

- Since the measuring effect take place inside a steel core, environmental

contamination does not influence the load cell’s performance and reliability. - A strong AC signal contributes to signal integrity as well as tolerance of electrical interference

Optima recommended ABB Pressductor® Loadcells for our drive system upgrades. In over 20 years of engineering drive systems upgrades we have successfully modernised:

- Metal processing

- Paper (both wet and dry end)

- Web laminating and printing

- Wet end belt sections

We can also provide training on loadcell applications such as how to select the correct loadcell for the application. From Radial Load Cells PFRL 101 to PillowBlock Load Cells PFTL 101 we will help you select the correct type for your application.

Loadcell Types:

Mini Series PillowBlock. The Mini Series are available in two versions, vertical and horizontal measuring.

- Measurement range: 0.01 to 20 kN (2.5 to 5000 lbs)

Standard Series PillowBlock. Machined from a solid block of steel, the

load cells are rugged and stiff, affording high overload protection as well as an extended measurement range above the nominal capacity.

- Measurement range (standard): 0.5 to 5.0kN (112 to 1125 lbs)

- Extended range: 0.75 to 7.5kN (169 to 1687 lbs)

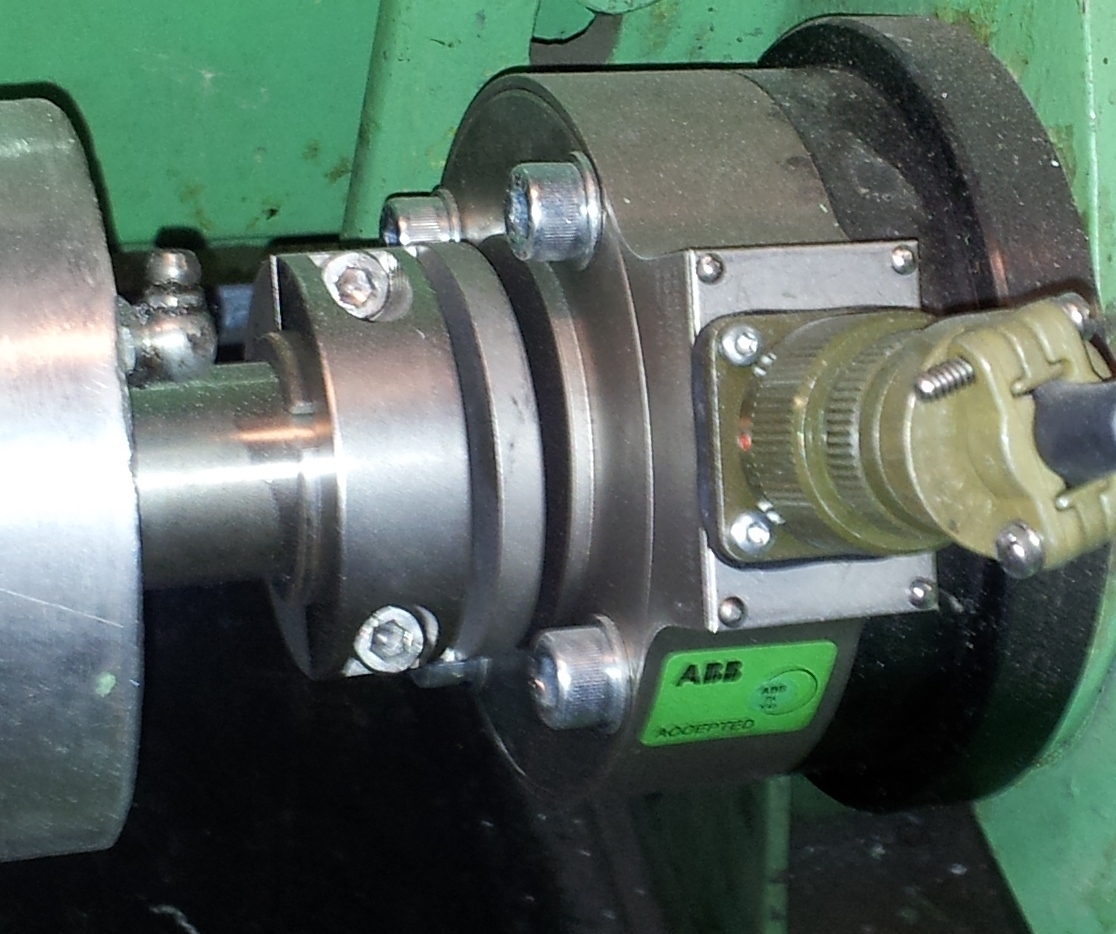

Radial Load Cells. For measuring web tension with shaft-mounted

load cells, the Pressductor® Radial Load Cell System (PRT System) is a high-quality system that provides exceptional and long-lasting performance.

- Measurement range (standard): 10.0 to 100.0kN (2250 to 22500 lbs)

- Extended range: 15.0 to 150.0kN (3375 to 33750 lbs)

Paper

Generally, paper machine applications require PillowBlock Load Cells PFTL 101

Converting and Printing

The PillowBlock Load Cells PFCL 301 and PFTL 301 are better suited for these applications. Alternatively, the Radial Load Cells PFRL 101 may be used as well.