Food & Beverage

Optima’s design methods and application techniques very often help our clients in the food and beverage sector to squeeze more production from their assets. More

Metals

From welding, coating, wire drawing, to destructive rope testing, Optima are very familiar with the production techniques in the metals industry. Upgrading machines from Bronx, Black Clawson, Process Line, Lemmerz and Georg amongst others. More

Packaging, Coating & Converting

Optima have in-depth knowledge of complex winders, tension controls and web transport systems. We have developed bespoke web transport solutions and upgraded production plant for end users in many countries. These include machines from Jagenberg, Bobst, Rotomec, Cerutti, Schiavi, Polytype, Atlas, Delta amongst others.More

Paper

We are pleased to be associated with some of the worlds best-known paper makers. Some machine upgrades include Jagenberg, Beloit Walmsley, Bone Markem, SanduskyWalmsley, Voith Paper, Valmet, Atlas amongst others. More

Printing

Following on from our understanding of complex winders, tension controls and web transport systems we have applied our knowledge of high performance web transport systems to control printing presses. Past upgrades include machines from Rotomec, Cerutti, Schiavi, Polytype, Atlas, Delta. More

Plastics & Rubber

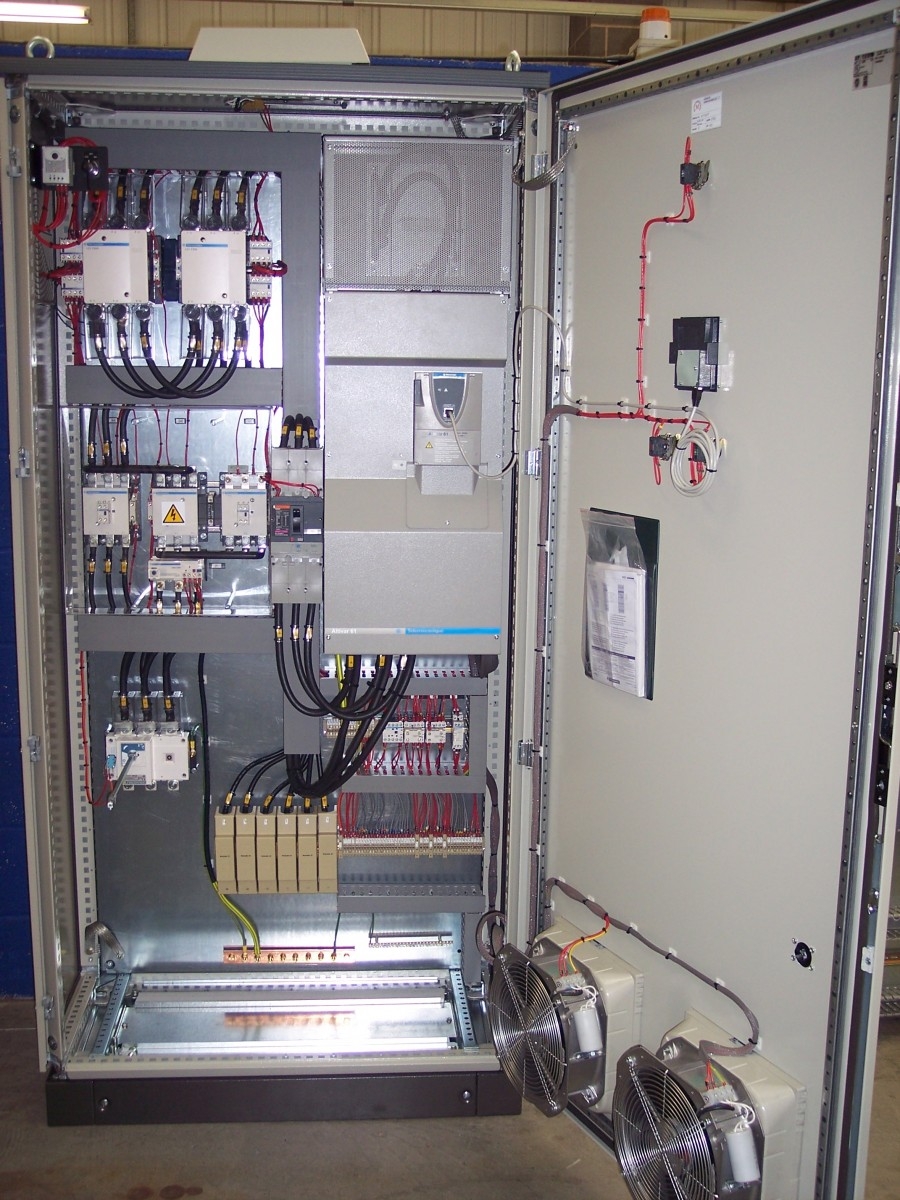

There are a number of critical issues that accompany production of polymers and plastics, be this system stability, temperature, speed or tension. The time it takes to get a stable set of conditions can make a significant difference to a business. At Optima we design our control systems to provide the fastest changeover and the most stable of operating conditions. Our portfolio of contracts has seen us upgrade machines from Bruckner, Davies Standard, Riefenhauser, Egan, Windmoller & Holscher amongst others.More

Aggregates

We have engineered energy saving projects to the Aggregates industry. Applying power saving inverter drives to the main fan, introducing automatic speed regulation with a differential pressure control loop and automatic filter cleaning warning mechanisms. Payback on these projects is typically less than 18 months and clients can often secure Carbon Trust funding for the projects.More

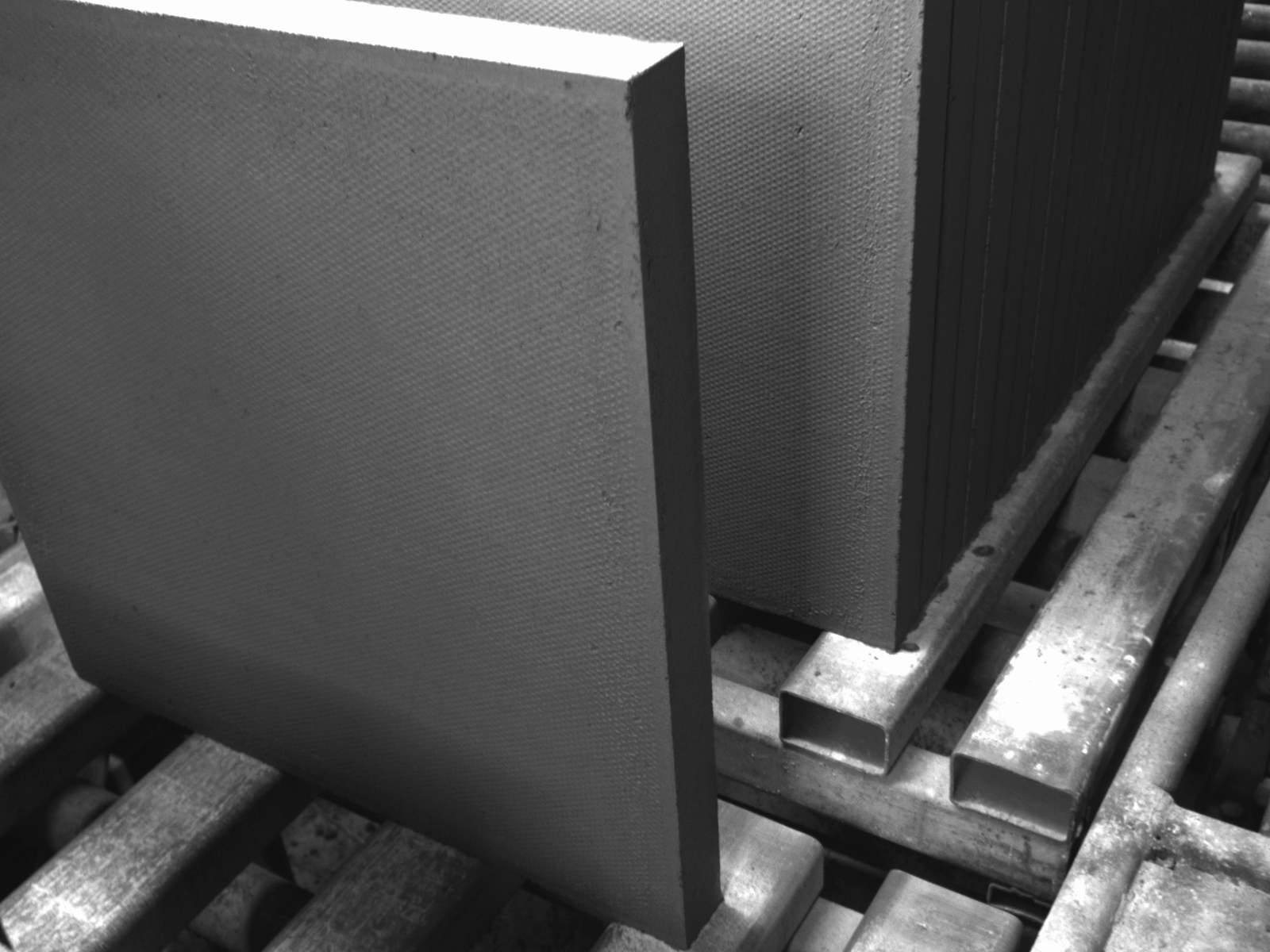

Building Components

Our portfolio of industrial projects includes systems engineered for the building supplies industry. Amongst which are systems for major industry players producing steel forming lines, insulation laminating lines and sub-terrainian reinforcing structures from extruded, formed and stenter treated polymers.More

Chemical & Pharmaceutical

This sector presents some of the more challenging environments for electrical systems. Highly explosive areas need to be accounted for in many of the system designs for chemical applications, Atex compliant systems are an inherent part of the solutions we provide to this sector.More

Corrugating

We have carried out numerous upgrade projects in this sector being suppliers to some of the major manufacturers in this market. More