The innovative #sinamics #G220 variable frequency drive from Siemens not only helps reduce harmonics (Gary Wilcock) but is also a more sustainable drive choice. Let us explain.

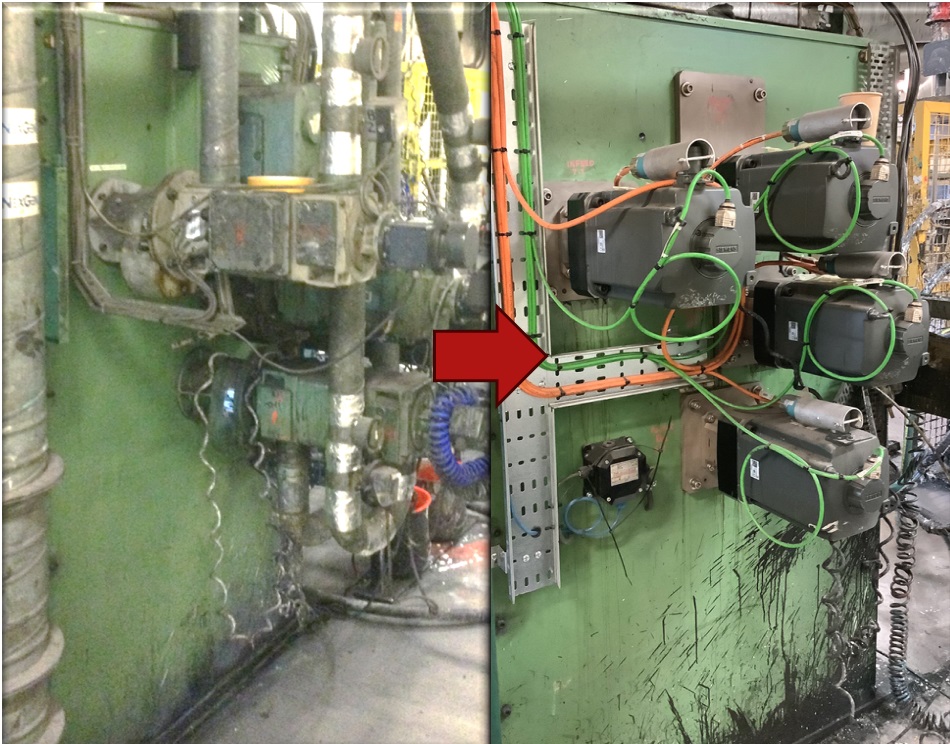

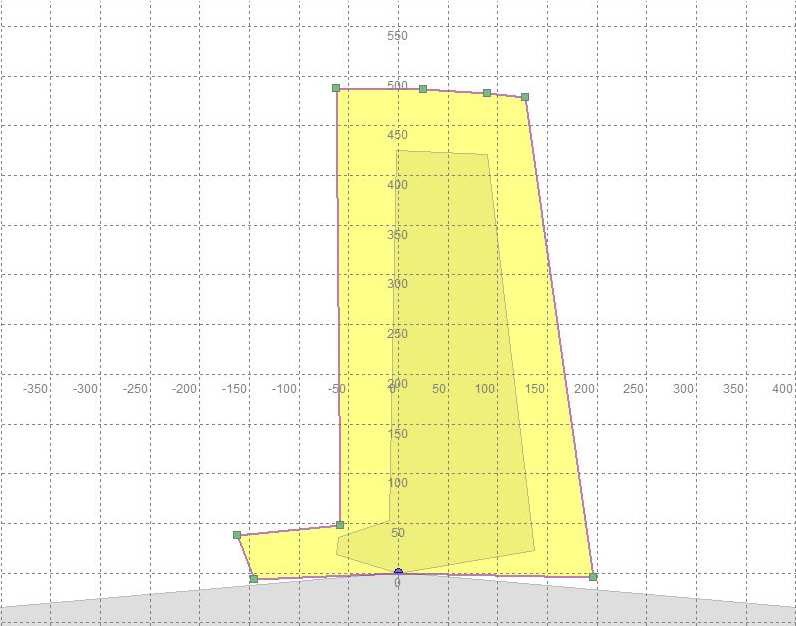

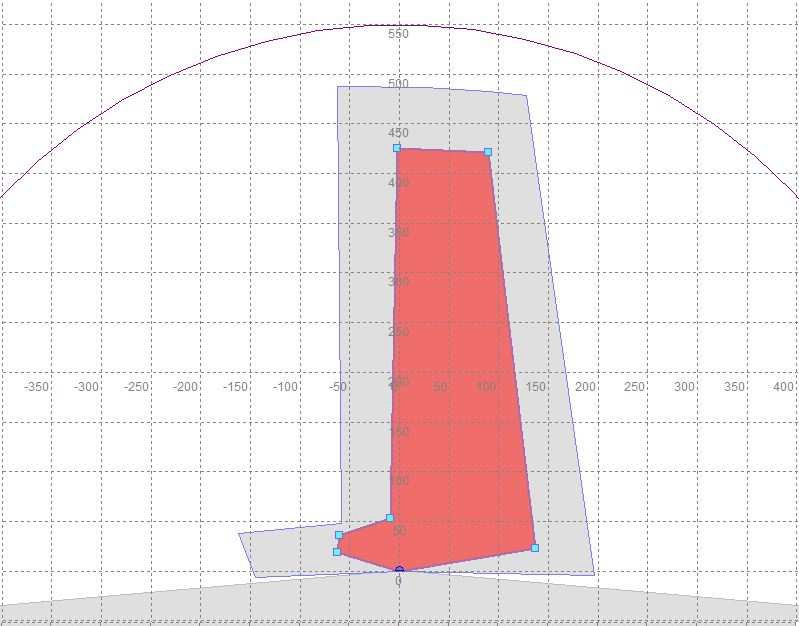

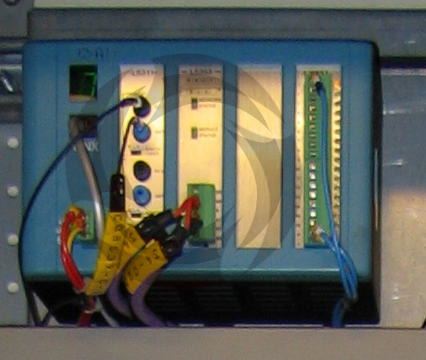

The animation below shows the draft panel layouts for 8 drives using the #G120 drives along with the required input and output reactors due to the long cable lengths involved for this installation.

It has helped Optima Control Solutions Ltd make this a more #sustainable design.

Not only have we have reduced #CO2 emissions in transit as the cabinet is lighter, we have also reduced the amount of #minerals required to build by avoiding additional #copper in the line chokes and #steel in the chokes and cabinets.

The fusing for the other 8 drives has been moved to an adjacent cabinet where there are other drive sizes located. The control panel build is now underway.

A big thanks to Ben Poole, too for his timely demonstration of these excellent drives. #Sustainability #CleanTech