Category Archives: Case Studies

Sustainable and Eco-Friendly Drive Technology from Optima

Continued Upgrade of Batch Plant

SINAMICS G Smart Access Module

Efficient Motion Control ATEX Coating

Full Project Turnkey Solutions

We are pleased to offer turnkey solutions to our clients. Depending upon the client’s brief and the project scope we very often manage the full project, including mechanical engineering and electrical installation. We have select sub-contract companies with whom we work regularly. Alternatively, we will readily work with customer-nominated third parties.

Our project management skills and application experience are valuable assets in this discipline.

On any project the facilities that Optima Control Solutions Ltd. provide are:

- Produce a detailed line control specification document

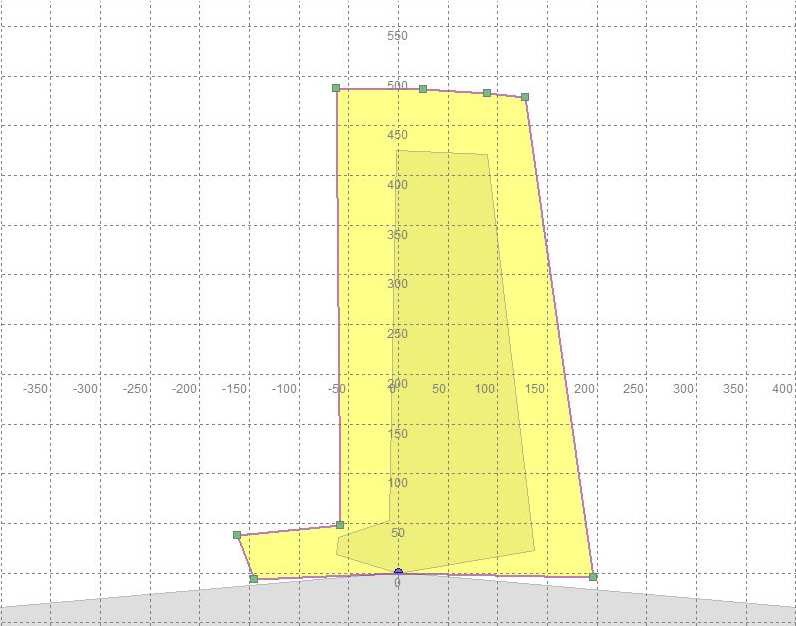

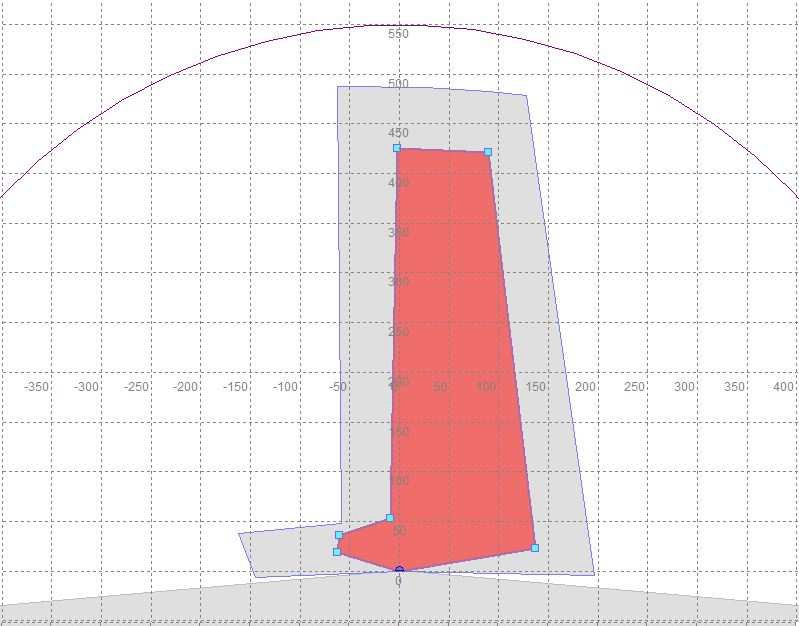

- Produce high quality CAD drawings

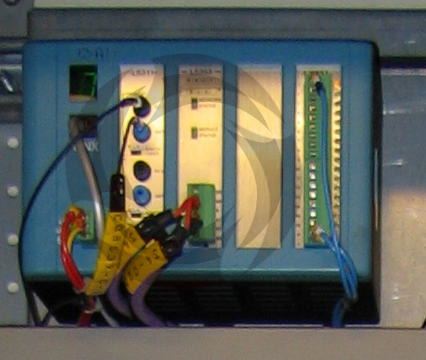

- Manufacture and functionally test your control cubicles.

- Ship the cubicles to your site

- Installation of the control cubicles (optional)

- Commissioning of the line control system

- Issue a fully documented User Manual

- Maintain a record of your drawings

- Provide an expert support service

- Equipment Installation.

Need more information? Browse various projects here. Our industry-specific pages also provide details about the control system projects we have completed over the years.

Safety Scanner Issues and EN999

Parker SSD Microtach Replacements

Cloud-based data dashboards

If you want to see how your machine or process is operating day in day out from anywhere in the world, where do you start?

An increasing number of companies are turning to remote cloud-based solutions for machine monitoring. Optima are pleased to offer our Cloud-based solution which keeps your automation hardware safely behind a secure firewall.

The video below shows a basic demonstration dashboard. If you would like to know more then please get in touch – we like to talk!

This video gives a very brief demonstration on how our Remote Access and Cloud Logging System can help you keep track of how your machine is performing. See when the machine is started, stopped, realise production metric data straight to your mobile, desktop or tablet.

We have been trialling our remote machine data dashboards #iot #industry4. These allow real-time data to be visualised from any PLC anywhere in the world to a PC, tablet or mobile ‘phone anywhere in the world! The system can communicate over 4G, Wi-Fi, or a direct Ethernet connection. From Kazakhstan (yes, we do have two units out there!) to Kendal (we haven’t got one there yet…), we have you covered for a very low monthly cost.

Our remote reporting dashboards which can send #production #reports by #email will shortly be ready for release.

With the increased risk of hacking of industrial devices becoming ever more prevalent Security Week – New Vulnerabilities Can Allow Hackers to Remotely Crash Siemens PLCs it’s not as simple as just hooking your PLC onto your local network.

Most of our clients prefer a SIM-card based system. The benefits of this system are that the equipment is always live whenever there is cellular reception available. Our range of antenna options mean that reception is possible even in the most remote locations.

For more information, please contact info@optimacs.com

Mark Lane.

Siemens Transform Event

Join Optima at the Siemens #Transform2022 Conference being held at the Manchester Central Convention Complex on 12th and 13th of July to explore how digitalisation of industry is being accelerated. For more information and to register for a complimentary space, see #Transform2022. Some of the key areas are:

- Edge and Cloud Data computing for machine diagnostics

- Improving plant operational efficiency and reducing energy consumption

- Use of resilient forms of energy

Join Optima, your trusted Siemens Automation and Drives partner at this event. It is the largest event that Siemens have ever organised in the UK so it set to be an event that shouldn’t be missed!

Join Optima, your trusted Siemens Automation and Drives partner at this event. It is the largest event that Siemens have ever organised in the UK so it set to be an event that shouldn’t be missed!